During a lightning discharge, an intense electromagnetic pulse is generated in an instant, inducing surge voltages and currents with high amplitude and rapid rise time in nearby devices or electronic circuits. These surges can cause devastating damage to sensitive electronic equipment. This is where overvoltage and surge protection components come in—to shield internal circuitry from damage caused by such transients.

Among the most commonly used voltage-clamping surge protection devices are:

TVS diodes (Transient Voltage Suppression Diodes)

Varistors (MOV – Metal Oxide Varistors)

Gas Discharge Tubes (GDTs)

All three components are designed to limit transient voltages, yet some users claim that TVS diodes are inferior to varistors and GDTs. But is that really the case?

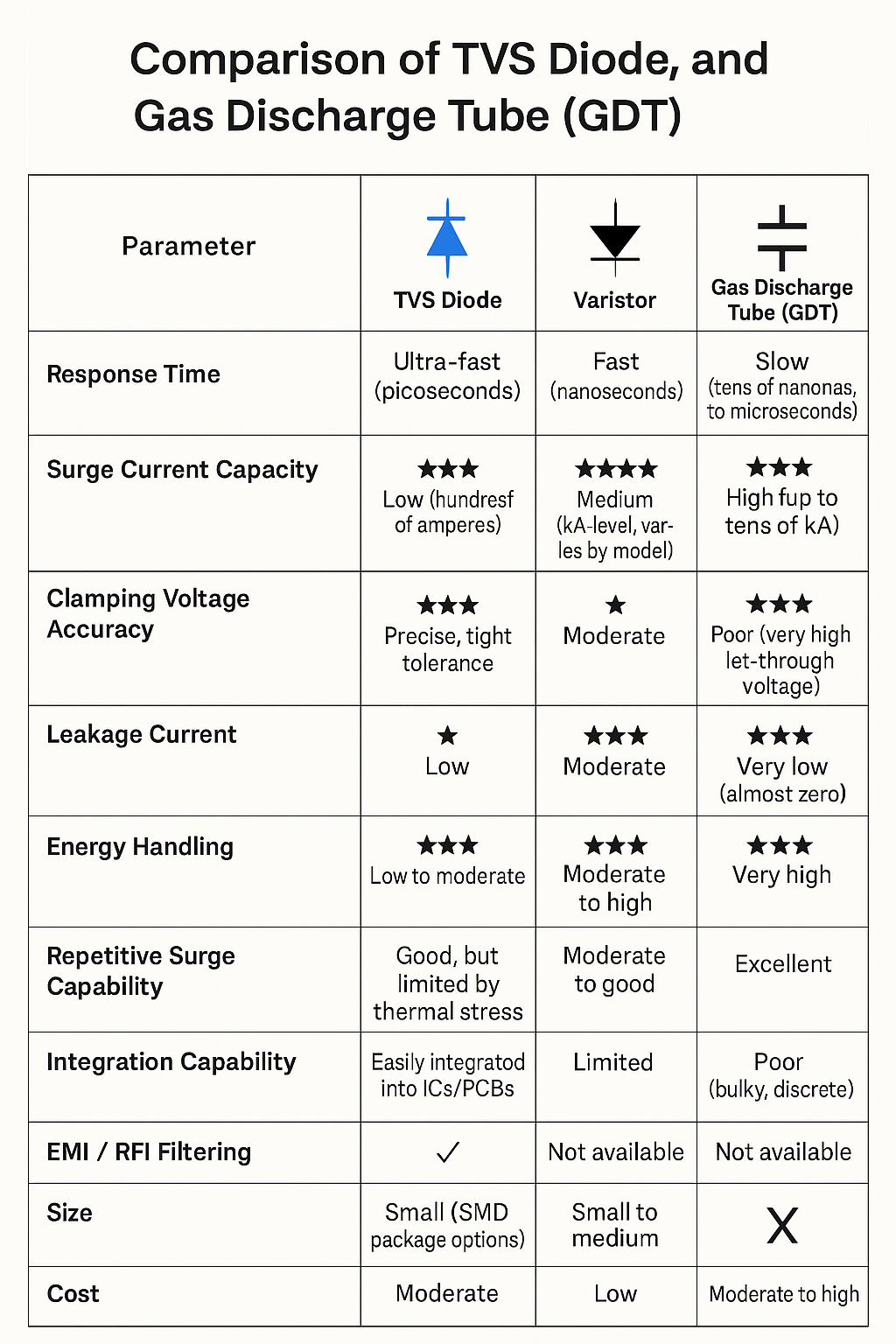

To truly understand their strengths and weaknesses, we need to compare them across several technical dimensions. This comparison helps not only with component selection but also with product design and application optimization.

Let’s dive into a technical comparison shared by an experienced FAE (Field Application Engineer), which highlights the three key aspects of these surge protection components:

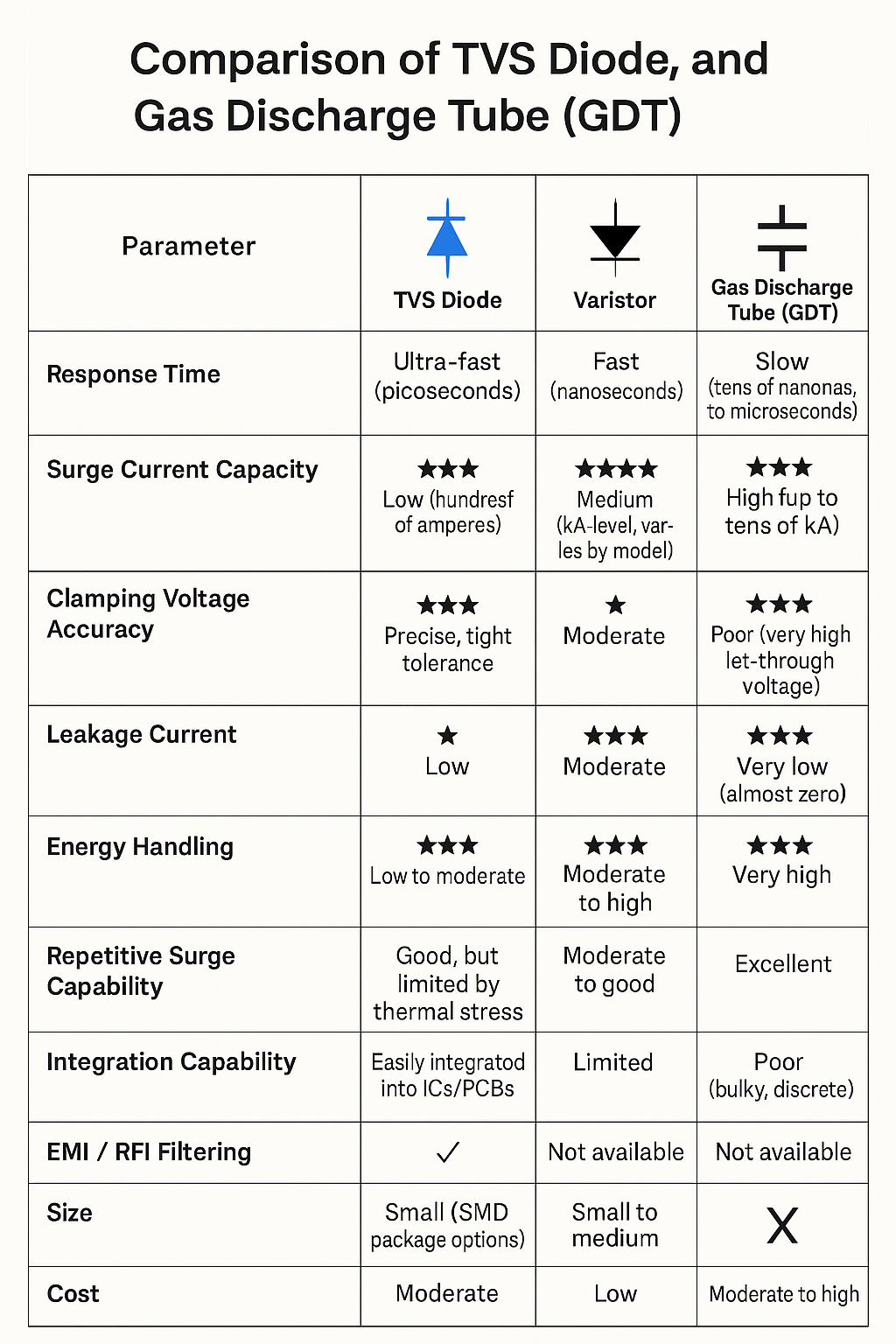

1. Response Time

Fastest: TVS diodes react the fastest, with response times in the picosecond range (10⁻¹² seconds). This makes them ideal for ultra-sensitive circuits.

Moderate: Varistors follow, typically reacting in the nanosecond range (10⁻⁹ seconds).

Slowest: GDTs are the slowest, requiring tens of nanoseconds or more to respond due to the time it takes for gas ionization to occur.

2. Surge Current Handling (Peak Current Capability)

Small: TVS diodes usually handle hundreds of amperes in an 8/20 μs surge waveform.

Medium: Varistors offer a middle ground. Depending on their rating, they can withstand several to tens of kiloamperes per surge.

Large: GDTs excel in current handling. Many are rated for tens of kiloamperes, and can survive hundreds of high-energy surges without degradation.

3. Operating Principle

TVS Diode: Operates based on the avalanche breakdown of a PN junction.

Varistor: Uses grain boundary barrier effects of zinc oxide ceramics to conduct at high voltage.

GDT: Relies on gas ionization and spark gap breakdown to conduct surge current.

Additional Insight: Integration Advantage of TVS Diodes

One of the unique advantages of TVS diodes is that they can be easily integrated with other functions on a single chip. Today, many TVS-based components come with built-in EMI filtering, RFI suppression, and other protections—offering space-saving, cost-effective solutions with improved performance.

Such integration also reduces layout complexity and minimizes parasitic inductance caused by PCB traces, which can be critical in high-speed and high-frequency designs.

Conclusion: Which Device is Better?

There’s no single “best” component—each has its strengths:

Choose TVS diodes for fast response, precise clamping, and compact integration.

Choose varistors for cost-effective bulk protection with moderate energy handling.

Choose GDTs for high-energy applications requiring large current handling.

A well-designed protection circuit may even combine multiple technologies to balance speed, capacity, and cost.

So the next time someone says TVS diodes are inferior—engineers might strongly disagree.

MCU Solutions

MCU Solutions PCBA Solutions

PCBA Solutions Bluetooth Solutions

Bluetooth Solutions

FAQ

FAQ Contact Us

Contact Us

Company News

Company News Technology News

Technology News Industry News

Industry News PCBA News

PCBA News

Company Profile

Company Profile Certificates

Certificates Terms & Conditions

Terms & Conditions Privacy Statement

Privacy Statement

Home Appliances

Home Appliances Beauty Appliances

Beauty Appliances Lighting

Lighting Kid's Toys

Kid's Toys Security Alarm

Security Alarm Health Care

Health Care

More information?

More information?